Our capacity to punch larger than standard turret surface areas enables the perforation and formation of highly detailed and accurate parts.

Turret Punching Services Brisbane

A turret punch is a machine that uses punching to form metal shapes. The process of turret punching means pushing through a piece of metal to create a hole. Turret punching can refer to a variety of holes in different diameters and can be more than one.

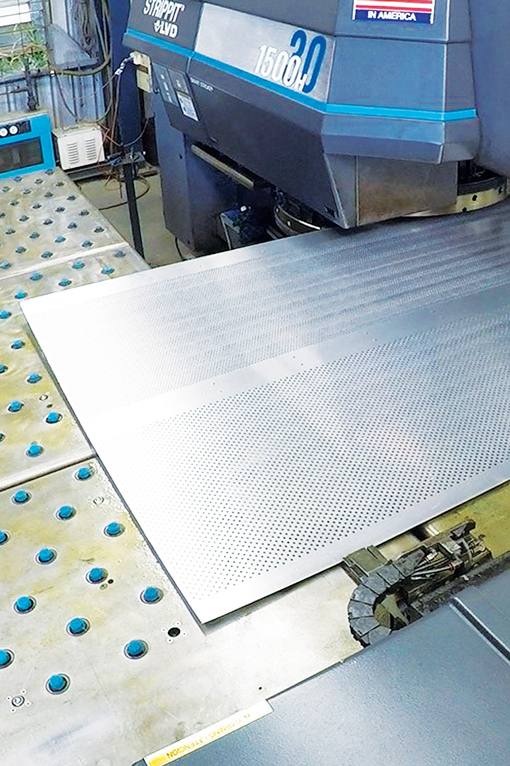

At Langford Metal, our capacity to punch larger than standard turret surface areas enable the perforation and formation of highly detailed and accurate parts.

Affordable CNC Turret Punching

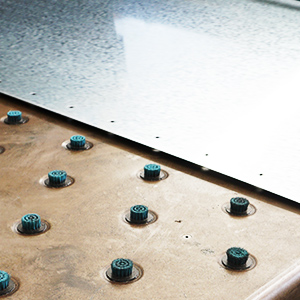

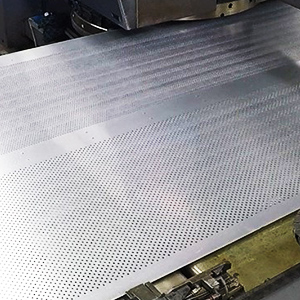

Langford Metal’s turret punching machinery and extensive tooling library enable the perforation and formation of single metal parts with detailed accuracy, to create extremely high-quality components without the use of heat.

By enabling round, square, rectangular and obround holes as well as dimpling, louvring, coining, multiple cluster tooling, and other perforations, we can take care of all your turret punching need. Langford Metal’s turret punching machinery is perfect for high volume, cost-effective manufacturing requirements when low-cost per component solutions are essential.

With the capacity to punch larger than standard turret surface areas up to 1500 x 4000mm, our material punching capabilities include aluminium, stainless steel, mild steel, galvanised steel, zinc anneal and PE plastics. We can punch holes in materials up to 5mm thick, dependent upon the size of the hole and material.

We also create custom tooling to exact project specifications and extend our tooling library each week. In short, if you have a detailed project in mind, we can handle it.

The Advantages Of CNC Turret Punching

There is a range of advantages associated with using CNC turret punching. When you need repetitive punching in your metal, choose Langford Metal to get it done. Some of the benefits of utilising turret punching include:

Design flexibility – Machines such as CNC make it easier to choose the configuration and size of your punches – giving you full control and flexibility.

Cost and time efficiency – With a CNC turret punching machine, you’ll be able to do more with less time and money. Turret punching allows for prototyping without any special considerations. Therefore, with a variety of configurations at your disposal, the tool allows for lower costs and a higher speed of production.

Modifiable designs – Turret punching services allow you to alter and change the design even after production has begun. Therefore, turret punches can be utilised for prototyping so that the system can be tested and then changed if necessary, without costing unnecessary time and money.

Why Choose Langford Metal For Turret Punching Services?

Our team of specialists at Langford Metal have over 70 years of experience and knowledge in the metal industry and are renowned for their expertise in metal fabrication and turret punching. For metal projects, from start to finish, Langford Metal have the appropriate skills to create the perfect design for your desired product. When you need reliable expert help and guaranteed success, choose our turret punching services at Langford Metal. There is a range of other reasons to choose us for your next project, including:

• Quick and efficient turnaround times

• Quality and precision

• An impressive knowledge about everything metal – from production to finish

• CNC turret punching with the latest technology

• Affordable pricing for all our services

• Highly dedicated to satisfying our client’s needs

• Professional workmanship and reliable service

• Effective customer service

• Design and prototyping services

No matter what your project is, we’ve got you covered At every step of your metal fabrication journey, our team at Langford Metal are here to help. When you need turret punching for design or functionality, choose our services.

With a range of shapes and configurations to choose from, and with a process that is both efficient and affordable, our CNC turret punching service is perfect for your metal fabrication needs. The next time you need turret punching, choose our expert team at Langford Metal and let us know what we can do for you.

FAQs

What is a CNC turret punch press?

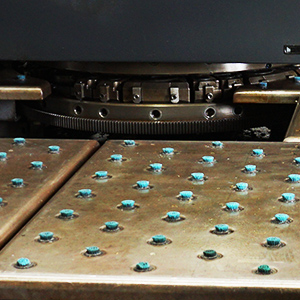

A turret press, or CNC (computer numerically controlled) punch press, is a type of metal press used to punch holes into sheet metal. A CNC turret punch can have up to 60 various punch tools to choose from. Using a controller, you can rotate the turret to move the necessary punchily tool into position. Punching tools can be multiple sizes or shapes, such as squares or circles. You can even combine various circles or squares to punch a more complex form. A turret press is beneficial in situations where you are creating many identical shapes in a row.

How does a turret punch machine work?

A turret punch machine forces a tool called a punch through sheet metal to create a hole. The punch often passes through the sheet metal into a die. A scrap slug from the hole is dropped into the die, which can then be discarded, reused or recycled. A turret punch machine is computer operated, so it is extremely precise. By inputting what you want into the computer, the device will position the sheet metal under the punch in the exact spot that you want. They also often use hydraulic and pneumatic power to press the punch through the metal.

What does a turret operator do?

A turret operator controls the turret punch press machine and punches holes in metal sheets, strips or bars. A turret operator will ensure that workpieces are aligned correctly on the punch and that the turret press is operating as expected. Other duties of a turret operator include following directions for machine settings for each cut, performing quality checks and conducting machine maintenance. A turret operator will also work the CNC program and may compute punch charts from blueprints. It is a turret operator’s responsibility to oversee the product’s assembly and ensure that it meets or exceeds client expectations.

What is a punching machine called?

A punching machine is used to punch holes into metal. They can be small and manually operated or larger and computerised. Smaller punching machines are often referred to as manual punching machines or punch presses. These may be found in home workspaces and are only effective on thin and smaller sheet metal. In industrial settings, computerised punching machines are more common. These are often referred to as turret punch presses or CNC punch presses. These are used on larger and thicker sheets of metal and are used in conjunction with computer programs.

Contact Us Today

At Langford Metal, we specialise in a range of services that will assist with your metal fabrication process. When you need something created out of metal and want the best quality from a team of professionals, we’re here to help.

Our CNC turret punching service will allow you to form precise, configured holes to match the needs of your overall design and project. We believe in working hard for our customers and therefore, we’ll dedicate our time to turning your vision into a reality.

For more information on our CNC turret punching service or any of our other services such as fabrication or electropolishing, contact us today or call us on 07 3088 9274.