Preparing and providing durable, high-quality finishes with our 100-metre-long powder coating line, spray booth and large batch heating oven.

Sandblasting and Powder Coating Brisbane

At Langford Metal, we’re experts at sandblasting and powder coating in Brisbane.When you need the perfect finish for your metal structure, our comprehensive powder coating services in Brisbane have you covered.

Our local industrial powder coating company offersr sandblasting, powder coating, and metal fabrication services that can protect and enhance the appearance of various metal surfaces, including aluminium, steel, and other alloys. In particular, powder coating is a popular method for protecting aluminium surfaces from corrosion and UV damage.

However, we understand that successful powder coating is an intricate task. Therefore, we ensure that our sandblasting process is done precisely and will prepare your metal structure for future powder coating.

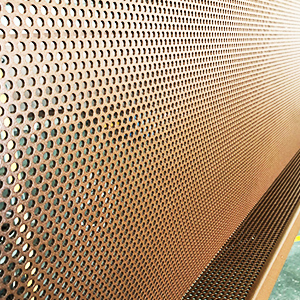

While we specialise in creating your desired metal structure, we’re just as interested in finishing your product correctly so that it exceeds your expectations. Therefore, we prepare and provide durable, high-quality finishes with our 100-metre-long powder coating line, spray booth, and large batch heating oven.

Powder Coating Brisbane

Powder coating provides a durable, high-quality finish. Langford Metal can protect and decorate anything from aluminium extrusions to fabricated steel frames with powders from the Dulux, Interpon, Jotun and Oxy-Tech colour ranges.

Our 100-metre-long self-automated powder coating line includes a de-ionising pre-wash, a drying oven, the main oven and reciprocal powder coating guns. All powder coated products have an accredited 10-year warranty.

Additionally, our heavy industrial powder coating Brisbane booth has a 31 cubic metre capacity and direct access to a large batch heating oven that can be extended up to 6.5 metres.

Sand blasting prepares metal surfaces for powder coating by removing rust and smoothing contours, enabling a longer-lasting finish. With a 31 cubic metre capacity booth, we can sand blast virtually anything. When you need sand blasting and powder coating services that enhance the final value of your metal product and increase its lifecycle, contact us at Langford Metal.

Why is Sandblasting Important?

Sandblasting is essential for a smooth, impressive paint or powder-coating finish. It will clean the surface, removing unwanted rough edges, coatings, and corrosion. This results in a high-quality finish for your metal product. Once the sandblasting is completed, the surface must be thoroughly cleaned to remove any traces of dirt, grease or sand that may interfere with the powder coating process. Nearly all your metal projects will need sandblasting to achieve the desired outcome; therefore, getting assistance from a leader in the metal industry is paramount. Choose our team at Langford Metal for superior sandblasting Brisbane services that will prepare your product for the perfect finish.

The Purpose Of Powder Coating

Powder coating provides a high-quality finish to your metal products. It’s the next step after sandblasting and ties the overall design of your project together. Powder coating gives your product a super tough finish, way better than liquid coatings. This makes it look good and shields it from the effects of moisture, chemicals, sunlight, and weather. So, you can forget about scratches, chips, rust, and fading – your product stays protected and looks sharp. With its increased longevity, powder coating is a smart choice when wanting a finish that is both durable and looks good.

Why Choose Our Sandblasting and Powder Coating Brisbane Services

When you team up with Langford Metal for your sandblasting and powder coating needs in Brisbane area, we ensure that you’re receiving reliable, professional, and high-quality services. We’ve gained 70 years of experience in the metal industry, meaning that we know how to create the perfect finish for a product and utilise our skills to meet and even exceed your expectations. Here are just some of the reasons why you should consider choosing us for your sand blasting and powder coating needs:

• We’re a team of trained professionals with advanced knowledge about metal production and finishing

• We utilise the latest technologies to provide the best results

• We’re dedicated to our work and guarantee only the best in the Brisbane area

• Our services are available at affordable prices

•• We are efficient with both project management and customer service>

We consider all your ideas and thoughts, ensuring you fully control the design and finishing process. We take your sandblasting and powder coating needs seriously and are committed to providing our best services. We don’t take shortcuts and refuse to finish a project without knowing if we’ve fully met your expectations and that you’re satisfied with our work. Therefore, choose our Langford Metal team for the perfect finish on your metal project.

FAQs

Where Can You Buy Blasting Sand?

You can buy blasting sand at most hardware stores, such as Bunnings. Different types of blasting media will work better for various jobs. If you need help with how your material will handle sandblasting, start with a gentler medium and work up to the more abrasive media. If you’re looking for an expert to tackle your sandblasting needs, give Langford Metal a ring today. We’ve got the lowdown on sandblasting and powder coating, and we’re all about guaranteeing the best results for your requirements.

How Does a Sandblasting Machine Work?

Sandblasting machines work to clean metal surfaces by abrading them with finely ground sand. This is done by using a high pressured air gun that fires out the sand at a very high velocity. Sandblasters typically have a ceramic barrel or another type of interior coating to prevent the sand from eroding the machine over time. Through consistent pressure, the sand that ejects out of the sandblaster works to remove the materials on the surface of the metal.

What is sandblasting?

Sandblasting is a process that uses a machine to spray abrasive finely ground sand under high pressure onto a surface. Most commonly, sandblasting is used to remove rust, paint, or any other unwanted materials from metal surfaces. As the sand particles hit the metal, they create a smoother and more even texture.

Sand is used because of its rough and gritty nature. For example, sandpaper contains many sand particles, and rubbing it onto a surface will create a smoother texture. Similarly, sandblasting uses sand particles in a very similar way, except instead of friction through rubbing, it uses heavily pressurised sand.

How Can You Make a Sandblasting Machine?

Even though it may seem appealing to DIY a sandblasting machine to save a bit of money, sandblasting can be a hazardous process. If you attempt to make a sandblasting machine yourself, your device will likely result from poor manufacturing. This can lead to severe health and safety hazards. We strongly recommend obtaining a sandblasting machine instead. If you are on a budget, sandblasting machines are available at a variety of price points. Alternatively, consider employing the skills of a professional sandblaster to complete your sandblasting job for you.

What is the finest sandblasting grit I can buy?

Glass beads are among the finest sandblasting grits available. They are helpful if you want a smooth, bright finish. Glass beads are often made from fine soda-lime glass and are recyclable, meaning you can use them up to 100 times before replacing them.

However, when choosing a sandblasting medium, it is essential to look at other factors aside from grit. Media are made of various materials, including walnuts, glass, steel, garnet and more. Each has a different hardness, size, and working speed that will suit other sandblasting uses.

What is a sandblasting machine?

Sandblasting uses highly pressured compressed air to propel media onto the project’s surface. A sandblasting Brisbane machine typically comprises four essential components: the air source, the sandblasting cabinet, the dust collector and the blasting media. The air source is usually an air compressor or bottle gas. The sandblasting cabinet holds the object that is being blasted. This ensures a closed system for sandblasting and will prevent the blasting media from getting on your skin or into your respiratory system. The dust collected is attached to the cabinet and is used to remove the dust inside. The blasting media is whatever material is being used for sandblasting in Brisbane.

What Is The Cost of Powder Coating and Sandblasting In Brisbane, Australia?

The cost of powder coating alone can range from $50 to $150 per square meter, depending on the complexity of the item and the type of powder coating used. Sandblasting alone can cost around $30 – $80 per hour.

It’s important to note that some companies may charge additional fees for preparing the surface, masking, and disassembly/reassembly of the item. To get a more accurate estimate, it’s best to contact our local sandblasting and powder coating company with specific details of your project.

Contact Us Today

If you want Brisbane’s best powder coating and sandblasting, come to us. We have the experience and equipment to handle large-scale projects.

A metal-related project is only complete with the proper finishing process. At Langford Metal, we specialise in sandblasting and powder coating in Brisbane to ensure your product is smooth, designed perfectly, and can withstand any tough conditions it may encounter. We build for longevity and take pride in our finishing services to ensure our customers receive the best we have to offer. Start your project right now with a free estimate. For more information on our sand blasting and powder coating Brisbane techniques, contact us today or call us on 07 3088 9274.